Corn

Corn harvesting

When it comes to harvest time, every minute counts, and harvesting at the right time and under the right conditions is crucial to achieving good results. The corn harvesting adapter used for harvesting must be reliable and able to perform its task without any loss of seeds.

We have extended the testing of our OptiCorn product family to remote countries such as the Republic of South Africa, where we had to perform well even among crop yields that are significantly higher than those in Europe, ranging from 18-a20 tons/ha. We are pleased to report that our adapter has passed with flying colors.

Introducing the OptiCorn Adapters

Features of OptiCorn:

- Easy drivability - improving combine's fuel consumption

- Can be adapted to any combine

- Minimal maintenance requirement

- Extremely low operating cost

- Excellent value-price ratio

- Equipped with overload protection - guarantees durability.

- High-performance stalk crusher - 5-6 cm stem chop

- The optimal harvesting speed range: 8-11 km/h

- Central electromechanical stalk roller adjustment

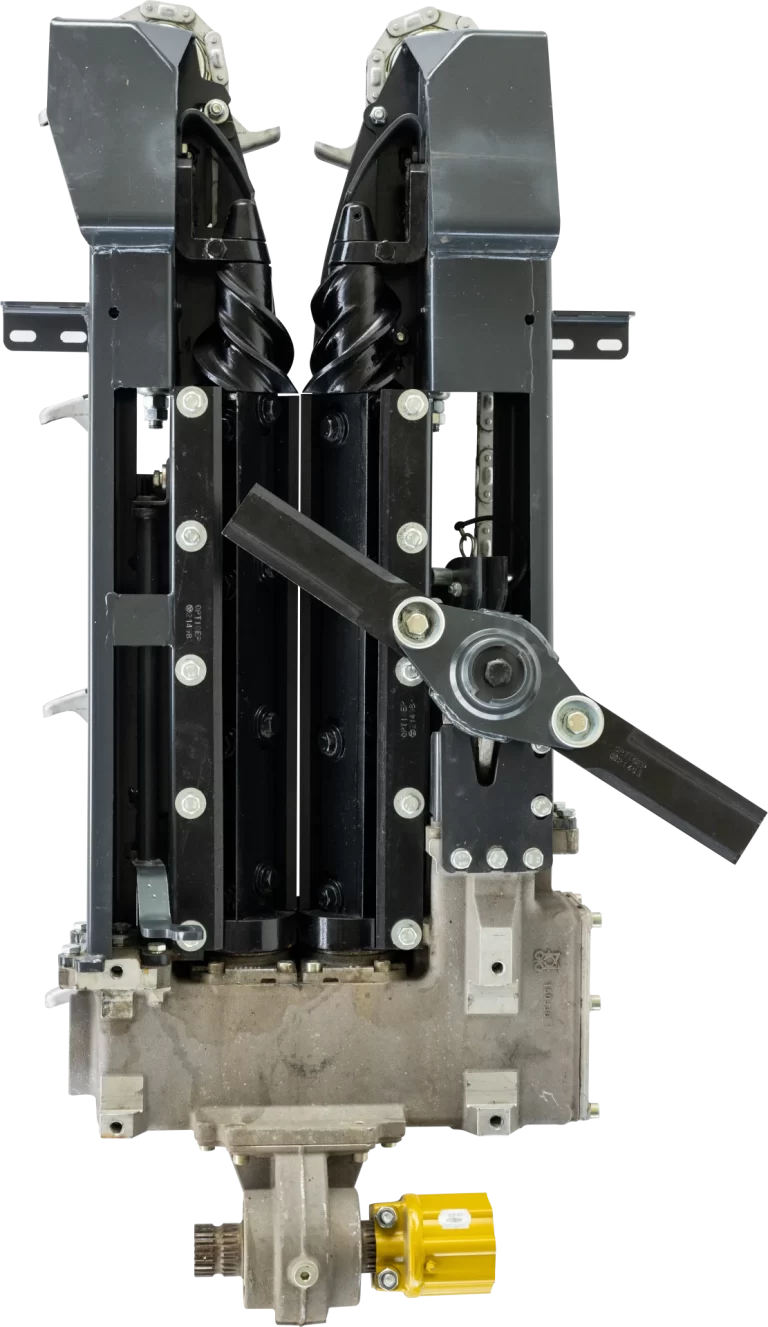

OptiCorn Snapping unit

Side extensions for

minimizing grain loss.

The design of the feed augers

ensures a consistent material

flow

Aluminum covers and row

dividers with steel reinforcement.

They can also be requested in

plastic version.

Rubber plates for

protecting against

flying corn pipes

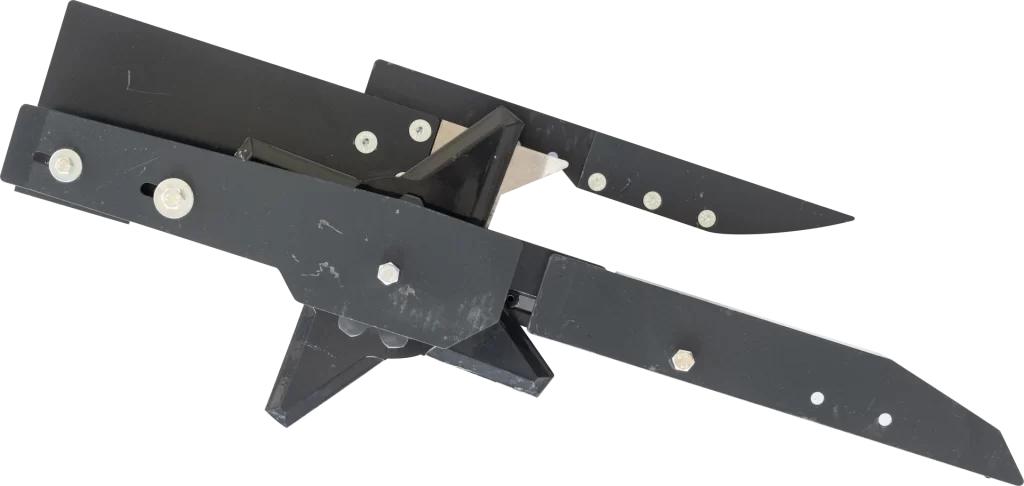

Knives

The knives of the stalk

chopper perfectly cover the

area of the breaking rollers,

resulting in perfect shredding.

Replaceable knives

The replaceable knives on the

breaking rollers are coated

with hard metal, which helps

with better straw pulling.

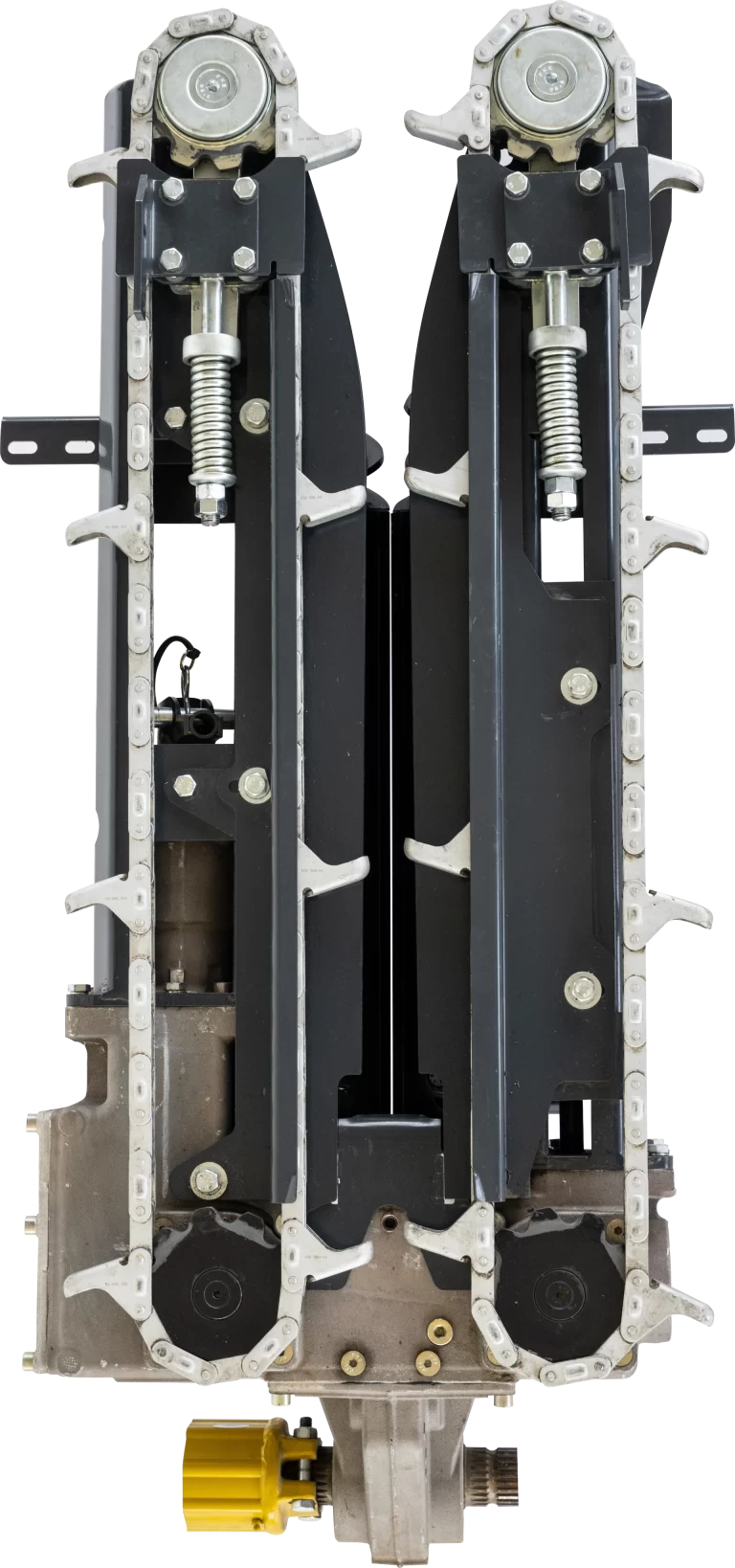

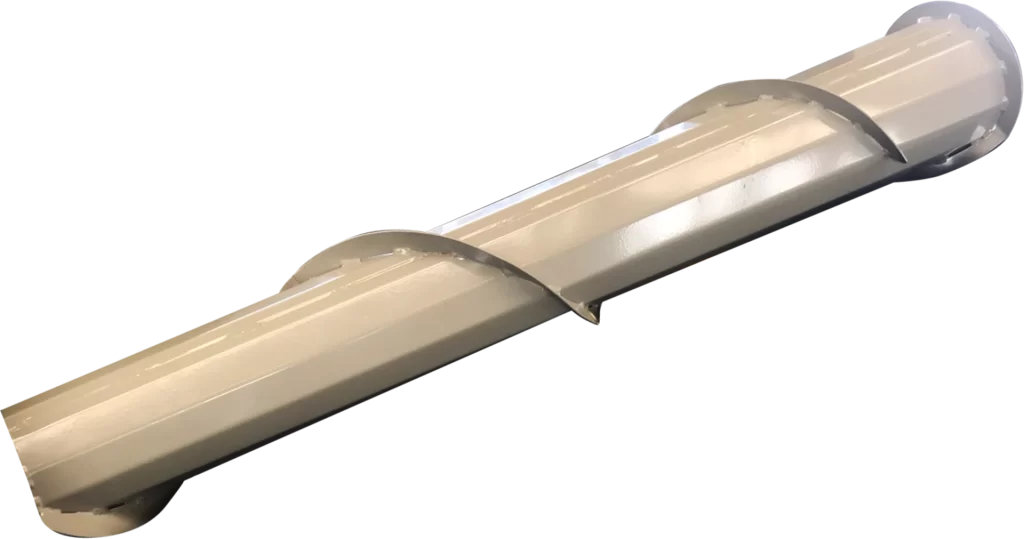

Stalk chopper

High-performance stalk chopper

with a speed of 2,450 revolutions

per minute, capable of chopping

the stalk residue to a length

of 5-6 cm.

Protective Switch

Overload protection -

Safety switch at every row

Breaking rollers

Extended breaking rollers

for gentle stalk pulling,

allowing for a clean job at

working speeds ranging

from 8 to 11 km/h

Semi-automatic chain tensioner

Reliably tensions the chain. The tension of the chain can be easily adjusted with easy access.

Tensioning sprocket

Made of heat-treated steel. It has an ideal diameter, which contributes to the fact that the snapping unit is less sensitive to the connector rows.

The special bearing arrangements ofthe breaking rollersdo not require

daily maintenance or greasing. Two deep-groove, sealed ball bearings are

built into a self-aligning housing, which is a completely maintenance-free solution

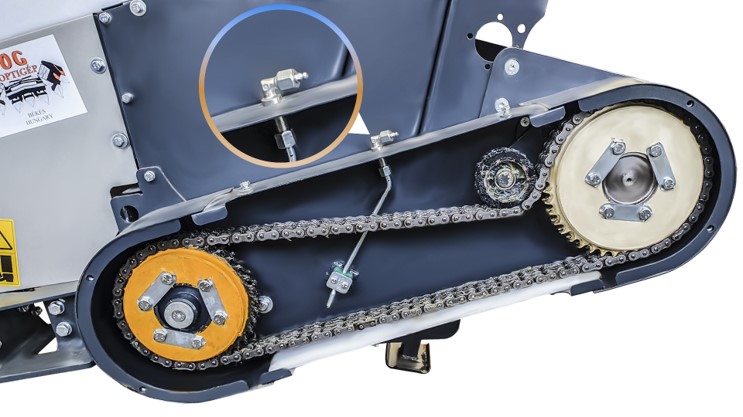

Closed side drive

The side drive operates in a completely enclosed system that is free from dust and contaminants, making it maintenance-free and providing users with a longer lifespan than average.

Side drive

We have removed the lubrication

points from the gearbox and

sealed the side drive, thus further

protecting it and simplifying

maintenance

We use a reinforced, ¾” duplex

chain - in case of changing the

harvester, the speed can be

adjusted by changing the

sprockets

Maintenance

The lubrication points of the

auger have also been led out of

the drive housing, which

simplifies maintenance

The chain tension can be

adjusted from outside of the

drive housing

Snapping unit row

Line-by-line protection

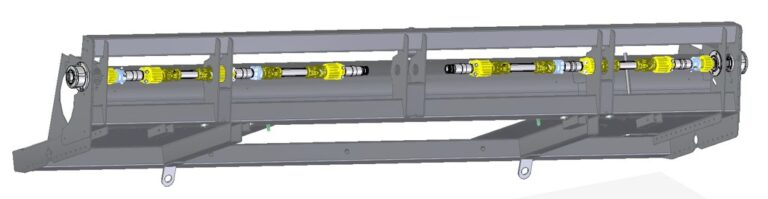

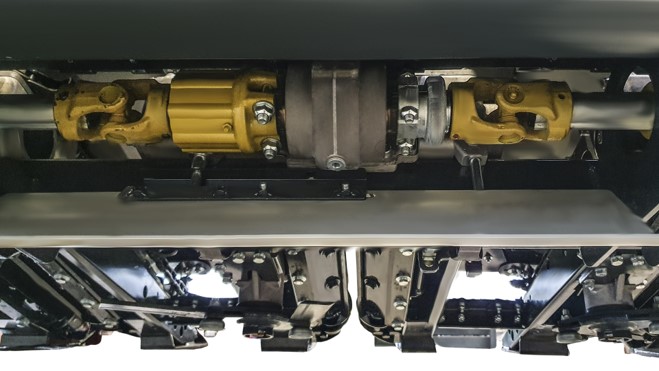

Cardan connection

The Snapping Units are equipped with line-by-line protection. The safe operation is ensured by a PTO connection between the snapping units.

It needs to be greased once before the season, otherwise it is maintenance-free.

The snapping unit is driven by: one-sided drive system from 2 to 5 rows and a two-sided drive system from 6 to 12 rows

The reinforced cover plate

serves as protection for the row of

snapping units against

mechanical impact.

Drive console

OptiCorn - OPTIONS AND DIMENSION TABLE

The position of the drive shaft

can be adjusted to the operator

combine's TLT. The drive

position can be changed in case

of a combine replacement.

Stubble stompers

The stubble stompers serve the protection of the combine’s rubber, it is also possible to install double (2 pairs) for wider tires.

AUTO HEADER HEIGHT CONTROL

The ground tracker ensures the optimal stubble height through automatic height control, resulting in excellent stubble appearance.

"Corn saver" rubber extension

The rubber collars attached to each row minimize grain loss.

Sunflower Kit / Sunflower inserts

Thanks to the sunflower kit that can be mounted on the OptiCorn corn header, sunflowers can be harvested with a simple conversion.

Rotary row divider

The OptiCorn corn harvester adapter effectively directs the crop into the machine even in wet and leaning crops.

| Type of adapter | Working dimensions | Shipping dimensions | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Name | Number of rows | Type of frame | Row distance | Lenght | Widht | Height | Lenght | Widht | Height | Weight |

| OptiCorn-470 | 4 | fix | 70 cm | 2965 mm | 2200 mm | 1500 mm | 2965 mm | 1200 mm | 2300 mm | 1450 kg |

| OptiCorn-476 | 4 | fix | 76 cm | 2965 mm | 2965 mm | 1450 kg | ||||

| OptiCorn-570 | 5 | fix | 70 cm | 3580 mm | 3580 mm | 1665 kg | ||||

| OptiCorn-576 | 5 | fix | 76 cm | 3790 mm | 3790 mm | 1850 kg | ||||

| OptiCorn-670 | 6 | fix | 70 cm | 4258 mm | 4258 mm | 2125 kg | ||||

| OptiCorn-670 CS | 6 | collapsible | 70 cm | 4258 mm | 4258 mm | In working position | 2400 kg | |||

| OptiCorn-676 | 6 | fix | 76 cm | 4738 mm | 4738 mm | 1200 mm | 2300 mm | 2175 kg | ||

| OptiCorn-676 CS | 6 | collapsible | 76 cm | 4738 mm | 4738 mm | In working position | 2700 kg | |||

| OptiCorn-870 | 8 | fix | 70 cm | 5638 mm | 5638 mm | 1200 mm | 2300 mm | 2775 kg | ||

| OptiCorn-870 CS | 8 | collapsible | 70 cm | 5638 mm | 5638 mm | In working position | 3150 kg | |||

| OptiCorn-876 | 8 | fix | 76 cm | 6072 mm | 6072 mm | 1200 mm | 2300 mm | 2850 kg | ||

| OptiCorn-876 CS | 8 | collapsible | 76 cm | 6072 mm | 6072 mm | In working position | 3420 kg | |||

| OptiCorn-1270 | 12 | fix | 70 cm | 8438 mm | 8438 mm | 1200 mm | 1200 mm | 4250 kg | ||

| OptiCorn-1276 | 12 | fix | 76 cm | 9120 mm | 9120 mm | 4500 kg | ||||