OptiSun adapters

Introducing the OptiSun adapters

Harvesting sunflowers without loss of yield

During sunflower harvesting, the combine harvester’s header is the first point of contact with the plants, which requires sophisticated technology and gentle treatment of the crop. This is the key to reach the maximum yield during harvesting.

The low-profile OptiSun sunflower header, equipped with seed-collecting shaking trays, uses an eccentric-driven shaking arm to continuously transfer sunflower heads into the auger trough. The crop cannot accumulate, so the seeds are delivered to the inclined conveyor without loss. Not a single sunflower seed is left in the field, allowing more yield to be collected.

Not a single sunflower seed will remain on the field, so even more crop can be put into the seed tank. Based on measured results, it guarantees an excellent return on investment with less than 0.5% seed loss even at harvest speeds of 10-12 km/h.

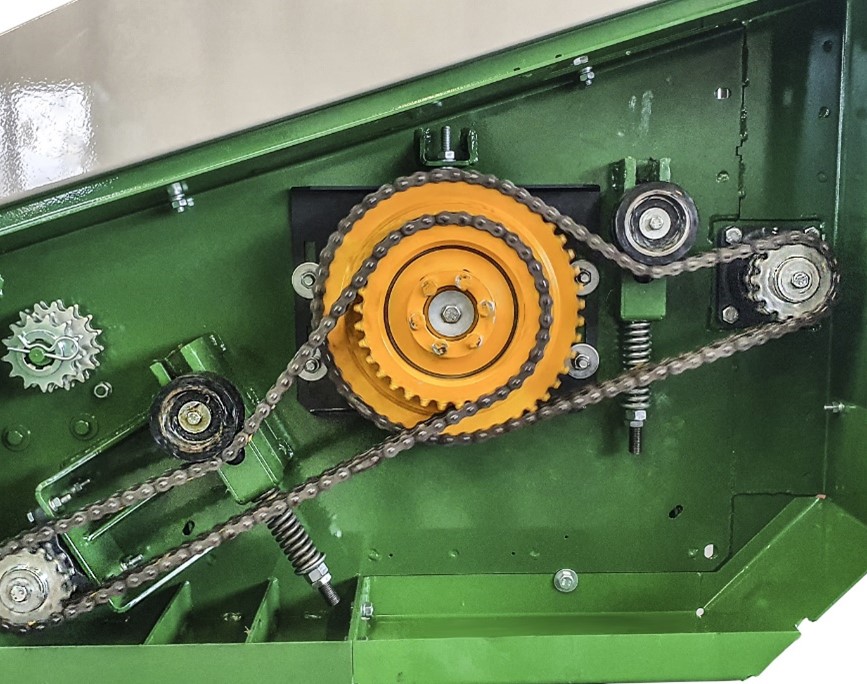

3/4" duplex chain ensures

reliable power transmission.

The spare chain wheel is an

accessory used to adjust the

speed of the individual units of

the adapter according to the

requirements of the crop or the operator.

Friction disc safety clutch to

protect the gathering worm

Spring tightened chain

mechanism

Every row is equipped with four

rotating blades and counter-blades.

Eccentrically operated shaking

arm and shaking trays for

efficient harvesting.

The ear chains arranged row by

row gently guides the sunflower

stems to the star knife cutting

mechanism. The OptiSun intake

system does not transmit

vibration to the plant, thus

preventing loss.

GONDOZÁSMENTES HAJTÁS

Side extension

The design of the side wall

ensures proper row selection,

thus preventing the plates of the

outer rows from falling out.

Protection net

The 600 mm high safety net

protects the sunflower heads

from falling out.

Row divider spikes

The optimally designed plastic

row dividers gently guide the

plant to the shaking tray.

The row dividers also lift the

bent or tilted stems, making it

possible to harvest the

crop from them as well.

Asymmetric shaking trays.

Right and left-sided trays ensure

a continuous material flow to the auger.

Large-diameter augers

With its 500 mm diameter, it

ensures a consistent crop flow

even for high-yielding crops.

OptiSun Information table

| Type of adapter | Working dimensions | Shipping dimensions | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Name | Number of rows | Type of frame | Row distance | Length | Width | Height | Length | Width | Height | Weight |

| OptiSun-470 | 4 | fix | 70 cm | 3040 mm | 2200 mm | 1500 mm | 3040 mm | 1200 mm | 2300 mm | 1020 kg |

| OptiSun-476 | 4 | fix | 76 cm | 3226 mm | 3226 mm | 1125 kg | ||||

| OptiSun-570 | 5 | fix | 70 cm | 3740 mm | 3740 mm | 1110 kg | ||||

| OptiSun-576 | 5 | fix | 76 cm | 3988 mm | 3988 mm | 1190 kg | ||||

| OptiSun-670 | 6 | fix | 70 cm | 4440 mm | 4440 mm | 1270 kg | ||||

| OptiSun-676 | 6 | fix | 76 cm | 4750 mm | 4750 mm | 1420 kg | ||||

| OptiSun-676 CS | 6 | collapsible | 76 cm | 4750 mm | 4750 mm | In working position | 1790 kg | |||

| OptiSun-870 | 8 | fix | 70 cm | 5840 mm | 5840 mm | 1200 mm | 2300 mm | 1640 kg | ||

| OptiSun-870 CS | 8 | collapsible | 70 cm | 5840 mm | 5840 mm | In working position | 2040 kg | |||

| OptiSun-876 | 8 | fix | 76 cm | 6274 mm | 6274 mm | 1200 mm | 2300 mm | 1710 kg | ||

| OptiSun-876 CS | 8 | collapsible | 76 cm | 6274 mm | 6274 mm | In working position | 2200 kg | |||

| OptiSun-1270 | 12 | fix | 70 cm | 8640 mm | 8640 mm | 1200 mm | 1200 mm | 2280 kg | ||

| OptiSun-1276 | 12 | fix | 76 cm | 9322 mm | 9322 mm | 2640 kg | ||||

| OptiSun-1670 | 16 | fix | 70 cm | 11440 mm | 11440 mm | In working position | 3790 kg | |||

| OptiSun-1676 | 16 | fix | 76 cm | 12370 mm | 12370 mm | 4000 kg | ||||